For uniform, cross-sector and international description of processes and specifications in cleanroom technology, standards are continuously developed and supplemented with current research findings and experience. Besides the ISO Guideline 14644, VDI is often used to establish standards. We present both guideline series and take a look at their relationships as well as differences in cleanroom classification in our blogpost.

CLEANROOM BLOG

Ina Henze-Ludwig

Last posts from Ina Henze-Ludwig:

ISO 14644 and VDI 2083: connections and differences

von Ina Henze-Ludwig, am Thu, Jun 14, '18

Behaviour rules in a cleanroom

von Ina Henze-Ludwig, am Tue, May 22, '18

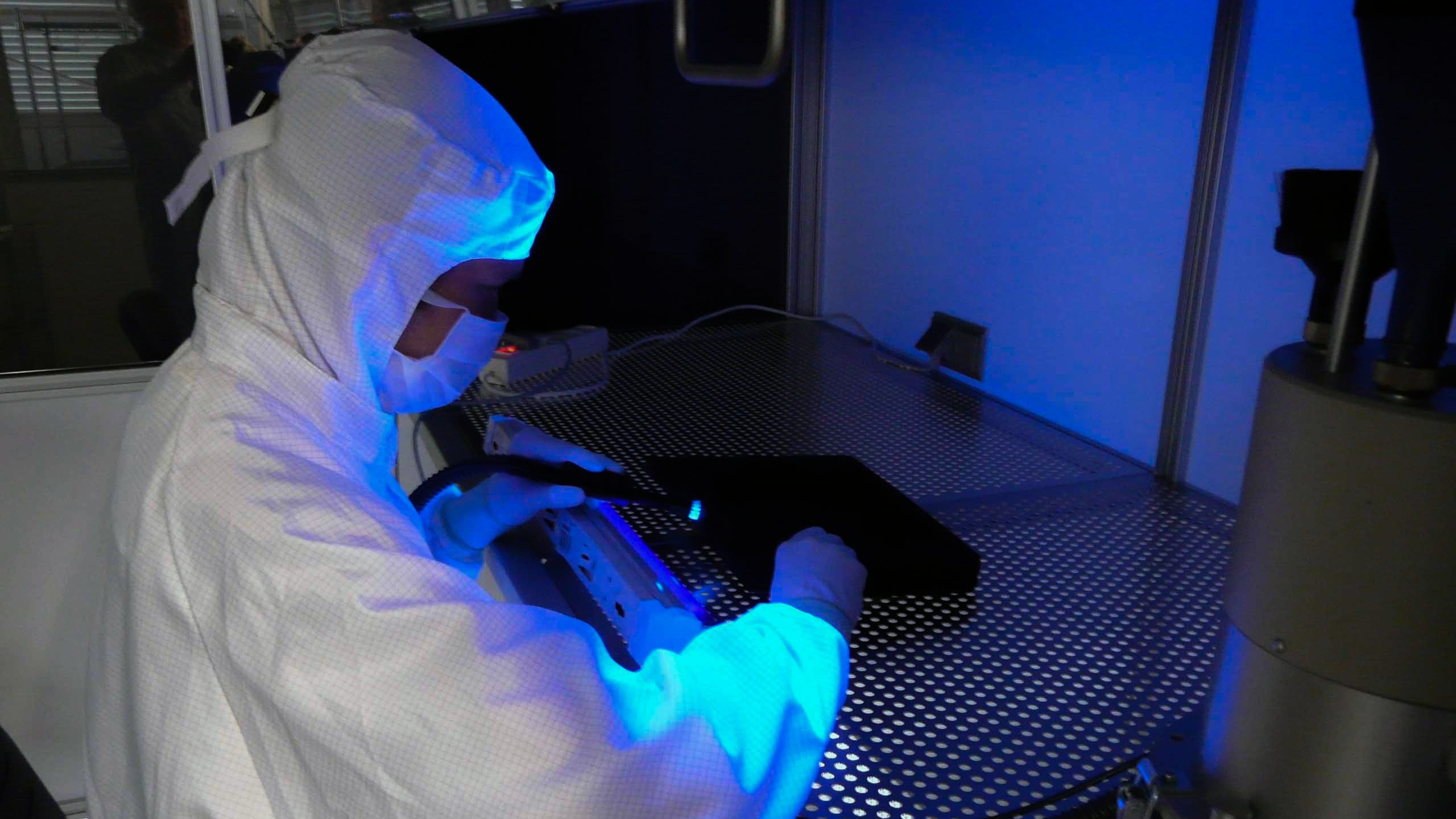

So that the cleanroom can maintain its air cleanliness class according to ISO, it is necessary to check all factors in the cleanroom for their cleanroom suitability and to optimise them, if necessary. Besides machines, assemblies and some processes in the cleanroom, it is above all the personnel who work there, that contribute significantly to the purity of the room. In this blog post, we give an insight into the most important rules of behaviour, which must be observed when working under clean conditions for employees.

Standardization in cleanroom technology

von Ina Henze-Ludwig, am Wed, May 2, '18

With the growing cross-country and cross-sector interest in cleanroom technology, the need for a uniform definition of cleanroom standards and norms grew. Due to the far-reaching and complex progress in the development of cleanroom technology across a wide range of areas, there were numerous standards and guidelines before uniform standardization. In our current blog post we outline the historical development of standardization in the field of cleanroom technology and give an insight into the current status quo of the most important guidelines.

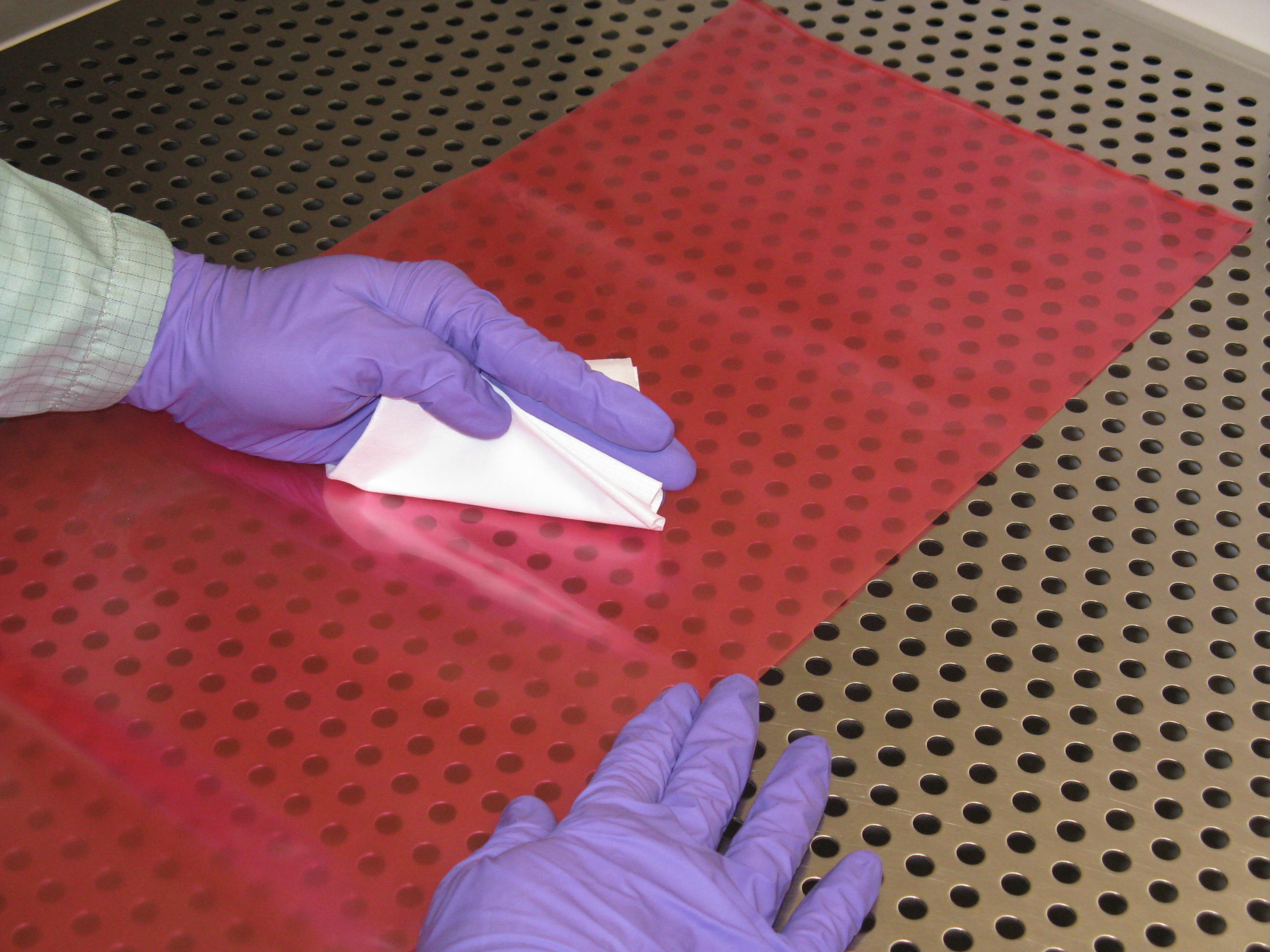

Cleaning in cleanroom conditions

von Ina Henze-Ludwig, am Tue, May 3, '16

- A cleanroom with a certain classification

- Repetitious cleaning to continuously remove the contamination

- Packaging of products before breaks and unpacking for further processing as well as regular cleaning

About this Blog

The cleanroom blog informs you about cleanroom technology.