- A cleanroom with a certain classification

- Repetitious cleaning to continuously remove the contamination

- Packaging of products before breaks and unpacking for further processing as well as regular cleaning

The question remains if a final cleaning of the machine would be sufficient. Since hardly any machine is easily constructed that all areas can be cleaned, this is not a practical solution. In case it is still done, contaminations are going to be “built-in” and become a long term risk. These contaminations don’t adhere to the surfaces for all times. Aging processes, change in surfaces charges (electrostatics), change of humidity and temperature etc. cause a change in adhesive force at the surface and give a non-predictable dynamic to the contamination.

Single part cleaning

The cleaning of single parts is subject to following factors:

- Kind of contamination

- Material

- Surface material and its sensitivity towards mechanical influences

- Impact of fluids

For a lot of applications ultrasonic cleaning proved to be best. It mostly spares the components and is technically developed. Many parts cannot be cleaned ultrasonically. Optics, ceramics, materials with porous surfaces and soft materials are part of this category.

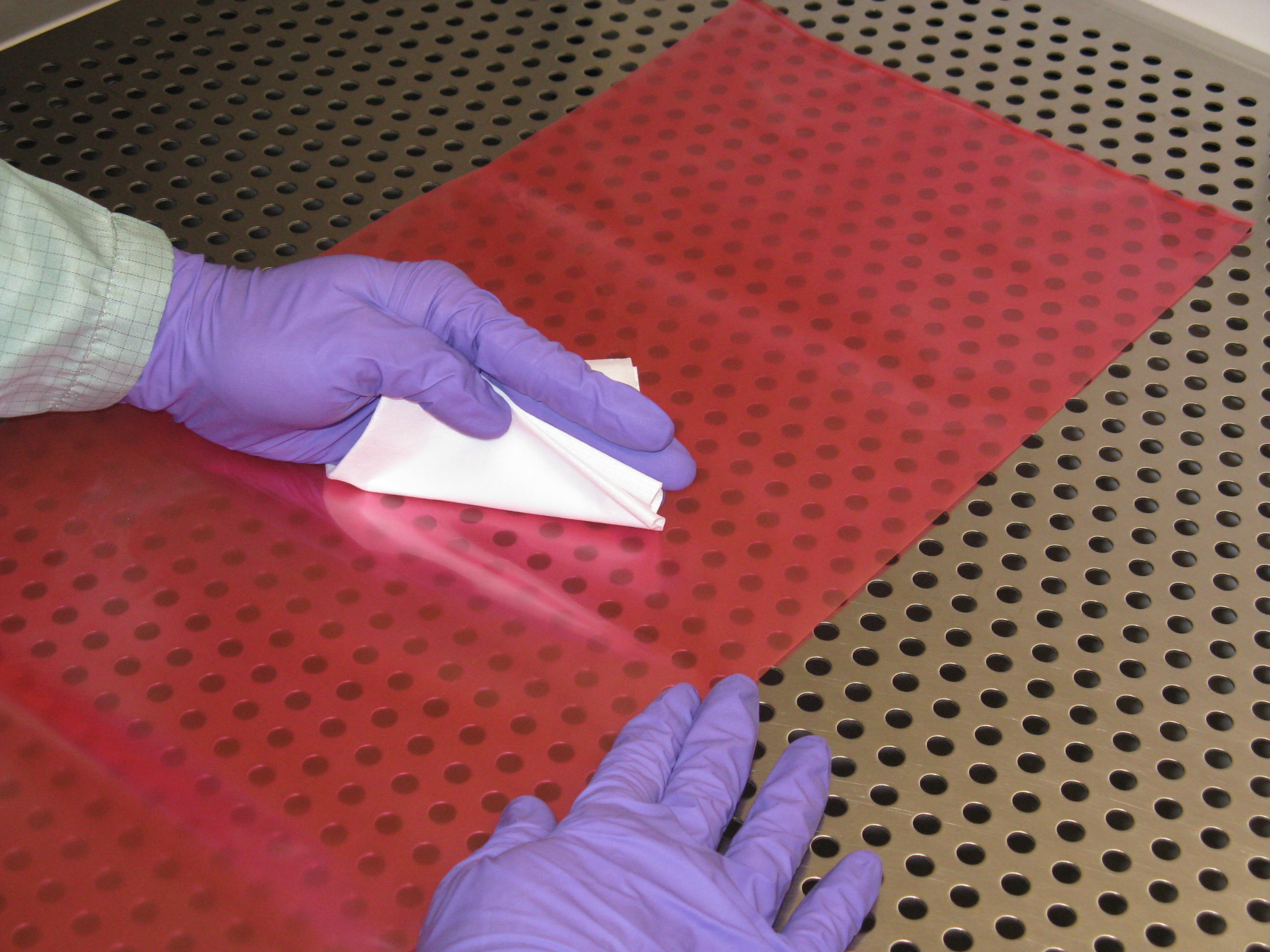

Mechanical cleaning with the support of suction discharge is the preferred alternative in these cases. Moreover, there are various additional cleaning methods as for example CO2 cleaning, “bake out”, “fishing”, scrubbing, or adhesive foils.

Component cleaning

The high complexity of components require a high amount of mechanical cleaning procedures, Bondings cannot be cleaned ultrasonically, for example, or the component is made of different materials which all require a different treatment. Residues of cleaning agents in the components are also a danger, since it is not possible to dry these 100%. The cleaning of components is most efficient if the parts have been cleaned beforehand.

Machine Cleaning

There is a differentiation between basic cleaning and maintenance cleaning. Similar to the cleaning of cleanrooms.

Basic cleaning following assembly

Before packaging of a machine at the producer’s it has to be cleaned – independently of previous cleaning steps of single parts and components. This cleaning acquires a personnel’s good knowledge of the machine. The different areas of the machine have to be cleaned with suitable cleaning methods to possibly spare sensible components from the final cleaning. These have to be protected beforehand. Immediately following the final cleaning the machine must be packed with the first protective cover (for example a foil). Before the packaging a Pre-Acceptancetest can be performed to show contamination problems already in-house. If elevated levels become apparent they can be removed easily at this early stage, which in turn costs less expenditures than the cleaning in the cleanroom at the customers’ facilities. These Pre-Acceptancetests are an easy way to document the quality for the customer.

Basic cleaning before commissioning

After properly unpacking the machine at the customers’ it undergoes basic cleaning again, to remove contaminations, which came about during transport, if necessary. Without this type of cleaning no machine should be taken into commission. Unpacking and cleaning regulations might be an asset. It is recommended to check the surface cleanliness on a random basis after the basic cleaning. The machine can be installed at its place in the cleanroom when the marginal values are fulfilled.

Maintenance cleaning

The maintenance cleaning is put into the customers’ cleaning schedule. It ensures the needed cleanliness over time. That means that the machines have to be restored to the initial state, even though the production is taking place in a cleanroom. Because the cleanroom conditions extend only the time frame until the surfaces of the process equipment are contaminated again. Additionally, contaminations, which are deposited on surfaces, are generated by the machine’s operation. It is difficult to constitute universal procedures for part, component and machine cleaning. The variety of parts is too vast and the requirements too different. Fundamentally, the single cleaning steps should be performed by trained personnel in consistently documented surrounding conditions. A quality control helps to develop the process further.