„Black labour“ – that sounds like tax evasions and informal economy. But it is essential for your business. Of course we mean measuring tasks in dark cleanrooms! Because in many applications, cleanrooms must not only be free of contaminations. They have to be dark as well! In this blogpost you will learn, which technical tool supports you simply as ingeniously.

CLEANROOM BLOG

Fan-Filter-Modules (FFU) with black filters

von Sven Huschenbett, am Wed, Mar 21, '18

Aspects of storage and transport in cleanroom conditions

von Andreas Hoffmann, am Tue, Oct 11, '16

Although it is frequently declared a secondary process, storage and transport of materials and products is enormously important for a company’s production processes. Especially for those, who work with high-precision and sensitive products which require cleanroom conditions for its use or processing. It doesn’t matter if it is for particle free components in optics, semiconductor, laser application or automotive technology.

Each and every one of these sensitive parts requires a transport, which complies with the high requirements for the storage conditions. As a result the requirements increased, especially for companies and suppliers in the High tech industry, where sensors and other extremely sensitive components are used.

Clean environment in the machine - A success story from experience

von Bettina Sachs, am Thu, Jul 14, '16

In more and more industrial companies it’s necessary to create a particle free environment, since the products are more and more sensible and can be damaged badly by particles accordingly. Even if the production environment is in a cleanroom, it is no guarantee that the integrated machine will have the same air purity class as its surroundings.

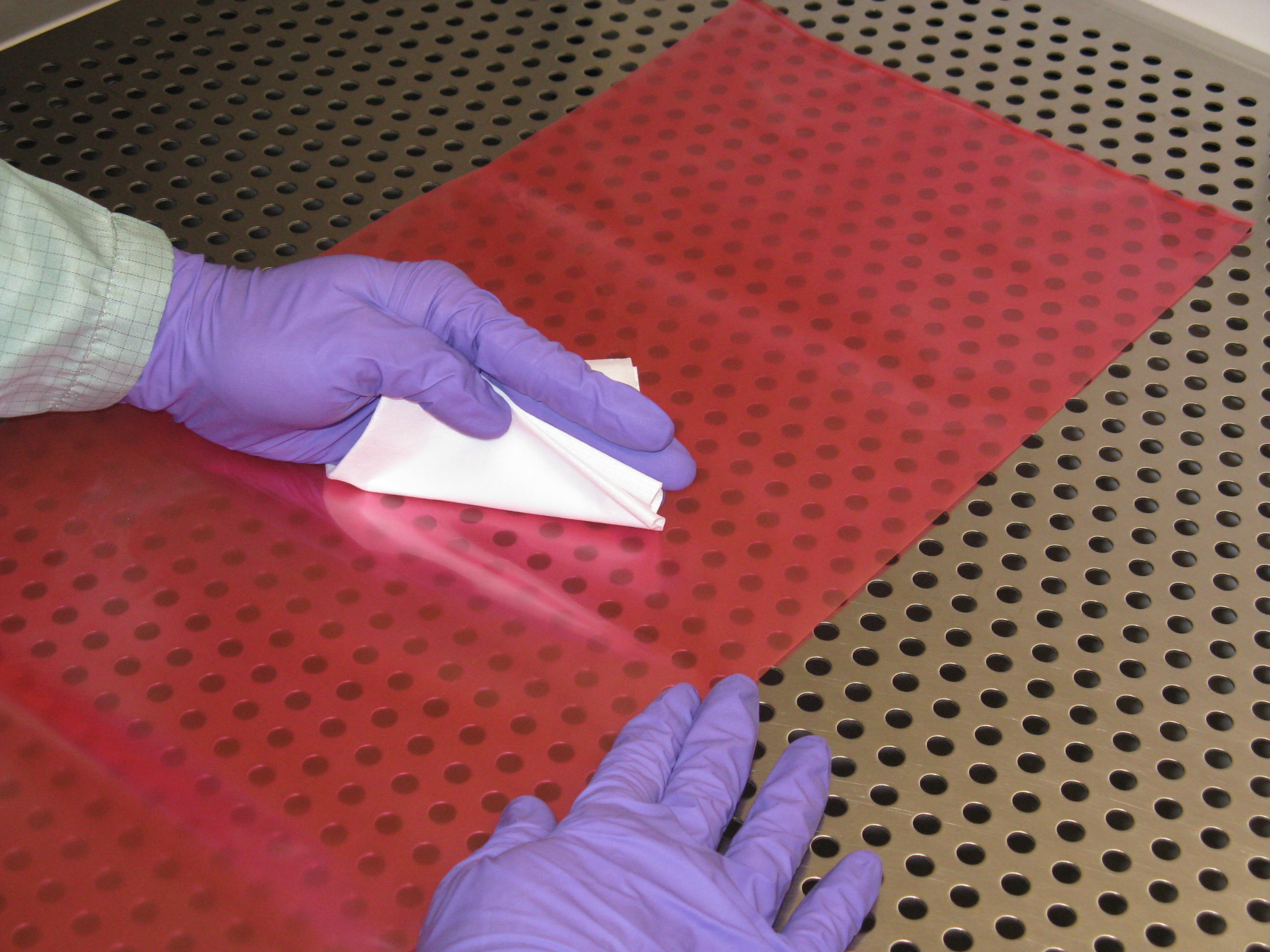

Cleaning in cleanroom conditions

von Ina Henze-Ludwig, am Tue, May 3, '16

- A cleanroom with a certain classification

- Repetitious cleaning to continuously remove the contamination

- Packaging of products before breaks and unpacking for further processing as well as regular cleaning

About this Blog

The cleanroom blog informs you about cleanroom technology.