To produce in cleanroom conditions a few important requirements have to be fulfilled. The analysis of the entire production chain is elementary in a clean production area, to produce efficiently in cleanroom conditions.

Often, it is neither clarified if the specifications for cleanliness of the delivered materials and process equipment are adjusted to the necessary requirements nor questions asked if the manner of delivery as well as cleanliness requirements for the product and its packaging are met.

The fact that it’s produced in a cleanroom doesn’t make the product quality sufficient.

Two processes inside the overall production chain which must be looked at critically, are cleaning and packaging of components, assemblies and complete machines.

Cleaning and Packaging - a new quality

Cleaning and packaging has always been done. New is that you can’t compare cleaning and packaging processes to “cleaning” and “packaging”.

Let’s have a look at an example. You’re giving your mother a nice vase for her birthday. You clean of sticky residue of glue from the price tag and wipe over it with a cloth, to free the vase from any other dirt residue. Afterwards you wrap the gift with wrapping paper. Done. Your gift is cleaned and wrapped.

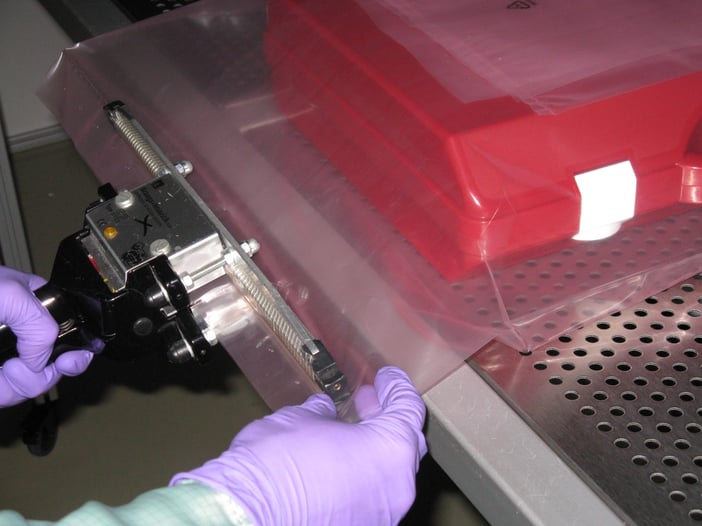

Let’s have a look at a cleaning and packaging process of an optical frame. It is cleaned with a cleaning agent and wiping agents through a predefined cleaning technology. The delivered optical frame sits in a stack box, which in turn is fixated in another lockable box. This box is doubly welded in pretreated and conductive PE film, nitrogen-purged or evacuated. It is send to the user packaged like that.

This short description reveals the differences to conventional technologies. But what requires greater effort for a cleanroom application?

Production steps and technologies, which need a clean environment, a cleanroom, use this to achieve a high product quality which would respectively not be feasible under “normal” conditions. The operation in a clean production process is usually coinciding with an exalted expenditure, which is accepted (product quality) or necessary (realisation). All outside influences which are negatively effecting this cost factor should be eliminated beforehand.

Norms and guidelines speak of topics concerning cleanroom and cleanliness suitability, surface cleanliness, chemical contamination and cleanroom suitable materials, however far the progress in the last years has gotten it still shows a fair amount of deficiencies.

With regard to a high product quality and a wholesome cost consideration it will be imperative to consider the entire process chain into the cleanliness system.

We’re looking into this topic in more detail in our whitepaper “Process development in cleanroom conditions – from component cleaning until the finished product”.